Offset printing - what you need to know

Offset printing is one of the most common printing methods used for mass production of printed materials such as books, magazines, brochures, postcards, and other documents.

The basic idea of offset printing is that a special metal plate with the desired image to be printed is created first. This plate is coated with a special substance that attracts ink or toner. The plate then transfers this ink or toner onto a rubber roller, and the rubber roller, in turn, transfers it onto the paper or other material being printed.

Offset printing has numerous advantages:

- High print quality: Offset printing provides high resolution and accurate image reproduction. It can reproduce vibrant colors, details, and fine lines, making it ideal for printing art pieces, magazines, books, and other high-quality printed materials.

- Color variety and shades: Offset printing allows for a wide range of colors and shades. It ensures precise color reproduction and can provide realistic and vibrant color effects.

- Efficiency for large volumes: Offset printing is efficient for mass production. Once the printing machines are set up, production can be fast and automated, allowing for printing large quantities without significant time and labor costs.

- High productivity: Offset printing enables printing on large paper sheets, which ensures high productivity. By being able to print multiple pages at once on large sheets, the number of required passes is reduced, speeding up the printing process.

- Wide material selection: Offset printing can be used on various types of materials, such as paper, cardboard, plastic, etc. This allows for its utilization in different types of printed products, including packaging, brochures, promotional materials, and more.

- Cost-effectiveness for large volumes: Offset printing is cost-effective for large print runs. When producing a large quantity of identical copies, the cost per copy can be significantly lower compared to other printing methods.

- Durability: Offset printing ensures high print durability against wear and external factors such as sunlight, moisture, etc. Printed materials can maintain their appearance and quality over an extended period.

Despite the numerous advantages, offset printing also has some drawbacks to consider:

- High initial setup cost: Offset printing requires the production of special printing plates and the setup of printing machines. This process can be costly and require significant financial investment. Therefore, if you only need to print a small volume of materials, other printing methods may be more economical.

- Limited flexibility for changes: Once the plates for offset printing are produced and set up, making changes to the printed material can be challenging. If modifications are needed for the printed document, new plates need to be made, and the setup process needs to be repeated.

- Longer preparation time: Offset printing requires time for plate preparation, machine setup, and material preparation. This can delay the printing process, especially for small volumes where task speed is crucial.

- Limited printing flexibility: Offset printing is most effective for printing identical copies. If personalized materials with unique data on each page are required, other printing methods such as digital printing may be more suitable.

Offset printing is widely used in various industries and fields.

Some of the main areas of offset printing application include:

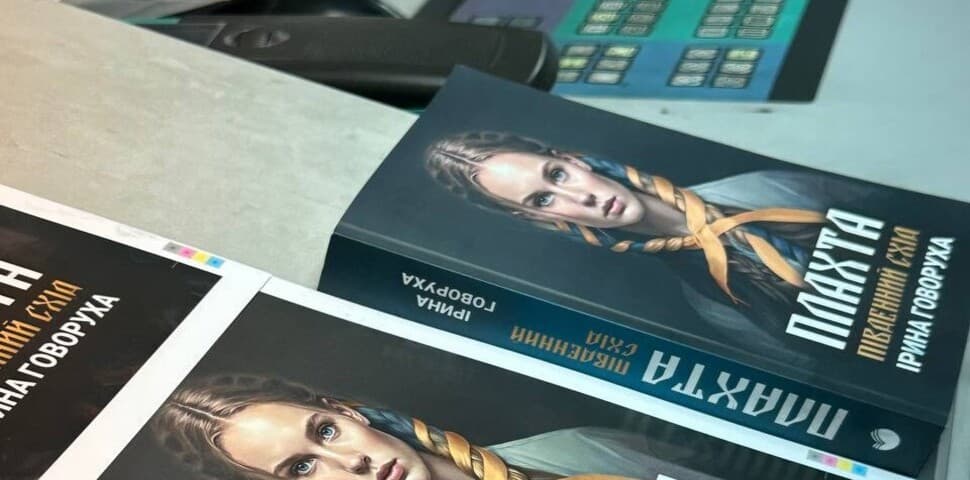

- Publishing: Offset printing is a popular method for printing books, magazines, newspapers, brochures, and other publications. It ensures high print quality, accurate image reproduction, and details, making it ideal for publishing.

- Advertising and marketing: Many advertising materials such as postcards, flyers, billboards, posters, and catalogs are printed using offset methods. It allows for vibrant, saturated colors and high-quality images, which are crucial for impactful advertising and attracting customer attention.

- Packaging: Various types of packaging, including boxes, wrappers, labels, and bags, are printed using the offset method. This enables vibrant design, logos, and product information on the packaging.

- Commercial Printing: Offset printing is used for the production of various commercial materials such as business cards, letterheads, tags, covers, brochures, and more. This printing method allows for a professional appearance and high quality for corporate materials.

- Artistic Graphics: Offset printing is widely used in the art industry for reproducing paintings, posters, engravings, and other artistic works. It enables the reproduction of details and colors from the original artworks.

These are just a few primary examples of the application of offset printing, and it can be used in many other industries where a high-quality, efficient, and reliable printing method is required.

If you're unsure if offset printing is suitable for your project, please contact us, and our professional managers will advise you on the best and most cost-effective solution that will meet your needs!

I want to print a book. How to do it?

In 2022, our printing house PP "SKD" purchased a FULL COLOR KBA Rapida 74 printing machine.